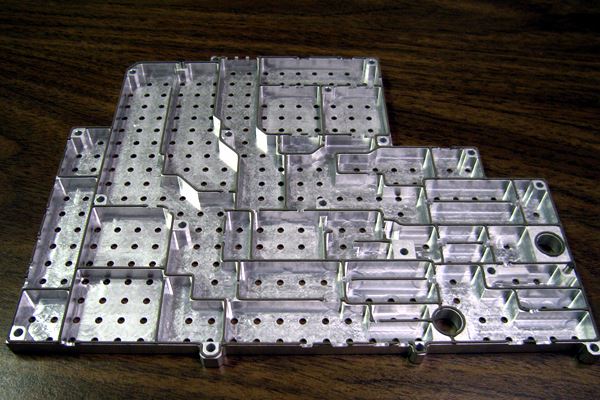

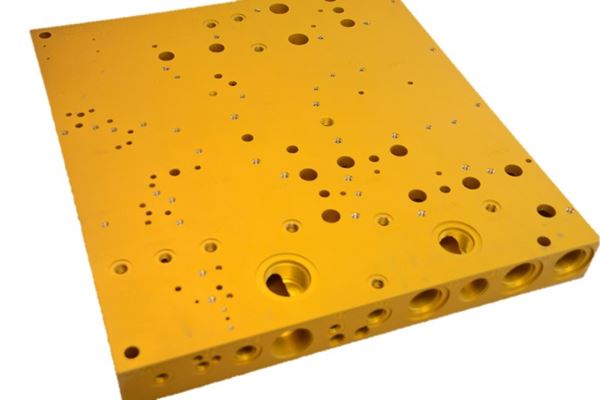

CNC Milling

Superior Technology, Inc. has a wide range of milling capabilities to meet our customer’s prototype and production milling needs. With the variety of machine sizes, cellular manufacturing layouts, interchangeable pallet systems, innovative tooling, and in-house fixture design & development allow us the flexibility of changing programs and tooling between machines, reducing set-up times and improving process repeatability. This elevates part quality and reduces set up and lead times, which translate to value for the customer, by improving quality, more competitive pricing and improved delivery dates

CNC Milling with 4th Axis available in both Vertical & Horizontal Configurations, with sizes up to 40″ x 30″ x 30″. Our High Speed Drill/Tap Centers and latest Mazak Palletech CNC Milling with 4th Axis, in both Vertical & Horizontal Configurations, Including Palletech – Flexible 12 Pallet Pool Manufacturing System & High Speed Drill Tap Centers for high volume production, with sizes up to 40″ x 30″ x 30″, allow dedicating customer tooling and fixturing can remain set up for ongoing high volume production, this allows repeatability and flexibility for JIT (Just-In Time) manufacturing.

Multi-axis milling is used for manufacturing a wide ranging from simple to complex including machining of exotic materials used parts such as machine parts, pump & valve housings, auto parts, tool components, automation & robotics components, test fixtures and tooling for Aerospace, Automotive, Industrial & Consumer Products, Optics and Precision Instruments, Medical Equipment, Military, Power Tool, Robotics & Automation , Rail and Transportation Industries.