Value Added Secondary Processes

Superior Technology, Inc. offers limitless internal and external managed Value Added Secondary Processes that add value and allow us to ship parts to customers finished complete Suppling complete certified parts to customers reduces their risks of sending parts to the additional suppliers eliminating logistics delays, part damage and unquantified part costs increases.

Working with our trusted vendors, some of whom we have over 50 years relationship with, we are able to manage all aspects of the process and guarantee the result, suppling certified parts which are traceable to many Mil-Spec’s and commercial specifications for all processes.

Common Processes Include:

|

|

Deburring and Part Finishing All parts shipped from Superior Technology will meet or exceed customer specifications for burr removal and surface finish requirements. This work is either done in process in the machining process to ensure accuracy and reduce additional part handling, or by abrasive vibratory tumbling, sandblasting, and Time-Saver machine graining. Additional this can be done by our skilled deburring specialists manually with precision hand tools, often under a microscope to ensure fine intricacies are meet and every part is fully inspected ensuring a high part quantity. |

|

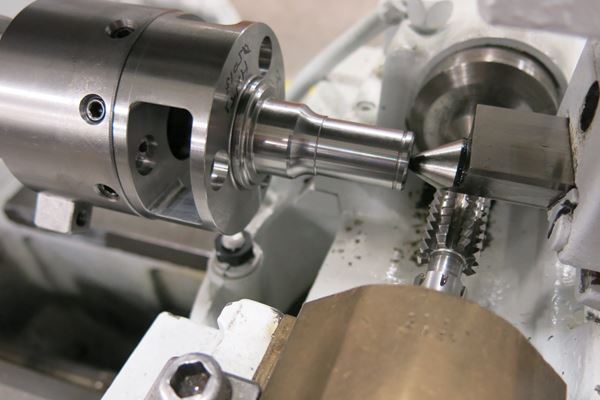

Hobbing, Broaching and Gear CuttingSpecialized machines are used to accomplish the customer requirements of internal and external gears, splines, serrations and slots, on rotors, shafts, spindles or other parts quickly and cost effectively. In addition we are able to broach flats, keyways, hexagonal, squares, splines, and other polygon shapes both internally or externally, as well as multiple knurl configurations. |

|

Heat TreatmentWorking with our trusted vendors, we are able to control all aspects of the process and guarantee the process, certifying and traceable parts to many industrial and Mil-Spec’s Available process include but are not limited to; steel case hardening, alloy steel heat treatment, induction hardening, nitriding, annealing, stress relieving, aluminum and copper alloy treatments. |

|

Plating, Paint & Specialized Surface Treatments

Available process include but are not limited to; aluminum anodizing, hard anodizing, chrome and nickel plating electro-plating, phosphatizing, blackening, PVD coating, paint, powder coating, and other surface treatments. |

|

Dynamic & Static BalancingDynamic & Static balancing is performed on parts up to 48” diameter and 400lbs to ensure vibration free operation of the parts. Out of balance material is removed by various methods to correct out of balance and ensure specifications are meet, for parts such as shafts, impellers, axles, hubs, wheels and brake rotors. |

|

Non-Destructive, Material Testing & Measurement InspectionIn house capabilities to perform NDT (non-destructive testing), metallurgical testing, and dimensional measurement inspections & reports with certifiable results. This can be done on manufactured parts by Superior Technology or as a contract basis for 1st article, short run or production inspections. Our in house capabilities included MPI (magnetic particle crack testing in a purpose built high powered testing machine, dye-penetrant crack testing, leak & pressure testing, coatings measurements, Torque Testing, and the full dimensional metrology measurement inspections in our inspection department. In additionally we working with trusted vendors who can perform almost any testing required including x-ray, hardness, tensile, SEM material chemical analysis, environmental and durability testing. |

|

Part MarkingPart Traceability is something we take seriously and marking of customer parts for identification, functional and decorative purposes can be performed by engraving, laser marking, pin stamping, Ink & stencil printing, hydrographic printing. |

|

Welding & BrazingWe are able to perform many welding operations certifiable to ASME AWS standards in Steel, Stainless Steel & Aluminum in a production environment, Production Brazing is available to make tube, fitting and other assemblies. |

|

Part & Ultrasonic Cleaning

All parts delivered form superior Technology will be delivered in a clean usable condition, free of chips and burrs. In addition we are able to perform specific cleaning and packaging to meet even the most stringent specifications, this can include Etching Passivation, Rust Inhibiting Ultrasonic Cleaning in many chemistries. |

|

Toolroom Fixtures

Our well-equipped tool room is available with a team of highly skilled journeyman toolmakers and design engineers, who design and manufacture tooling and fixtures, for all of our production needs, this reduces lead times and allows continuous improvement to be quickly implemented. |

|

Production SawingWe cut all of a blanks in house using out automatic saws, this saves time, material cost and allows production flexibility. This is available as a service to customers to who have specific needs. |